The Most Common Shrink Sleeve Labeling Questions Explained

What is a shrink sleeve label and how does it work?

A shrink sleeve label is a shoulder/middle body, full-body, full body and cap, or multi-pack label made from plastic film that’s applied over a container and then shrunk to fit using heat. Unlike traditional pressure-sensitive labels, shrink sleeves conform tightly to the shape of the package—even complex or contoured designs.

What is the difference between a shrink sleeve and a traditional/pressure-sensitive label?

The primary difference between a shrink sleeve label and a traditional pressure-sensitive label lies in application and coverage. Shrink sleeves are applied over a container and heat-shrunk to conform tightly to its shape, offering 360° full-body coverage and excellent performance on contoured or uniquely shaped containers. Pressure-sensitive labels use adhesive to bond directly to the container surface and typically provide partial coverage, making them best suited for standard or flat containers. The right choice depends on your container design, branding goals, and production requirements.

What types of containers can use shrink sleeves?

Shrink sleeves can be used on a wide variety of container types and materials, making them a highly flexible labeling option. They are especially effective on containers with curves, tapers, or unique shapes where traditional labels may not apply smoothly. Common applications include plastic bottles such as PET, HDPE, and PP, as well as glass bottles and jars, metal cans, and certain composite containers. Because shrink sleeves conform tightly to the container when heat is applied, they are ideal for achieving full 360° coverage and strong shelf appeal across food, beverage, health, beauty, and household products.

What materials are used, and which is better?

Shrink sleeve labels are most commonly made from PVC, PETG, PLA, and OPS. The correct material depends on your application and sustainability goals. PVC (Polyvinyl Chloride) offers strong shrink performance and is often more cost-effective, making it suitable for simple container shapes and budget-conscious projects. PETG (Polyethylene Terephthalate Glycol), while typically more expensive than PVC, provides superior clarity, more consistent shrink properties, and is widely considered more recycling friendly. PLA (Polylactic Acid) is an easy-to-print, biodegradable material that produces a smooth, glossy finish at low temperatures. While it is more brittle and less heat-resistant than PETG, it is most commonly used for compostable packaging applications where sustainability is a priority. OPS (Oriented Polystyrene) is lightweight, easily compressed, and best suited for clear containers, cups, and food packaging that require squeezability.

How do I measure my container or size the sleeve correctly?

Properly sizing a shrink sleeve starts with accurately measuring your container’s height, diameter, and shape changes from top to bottom. Measurements should include the largest and smallest diameters, overall label height, and any curves, tapers, or neck finishes that could affect how the sleeve shrinks. These dimensions are used to calculate the flat width of the sleeve and the required shrink percentage so the label conforms smoothly without wrinkles or distortion. Because container geometry and material behavior can vary, working with a packaging technician is recommended to confirm sizing and ensure optimal fit during application.

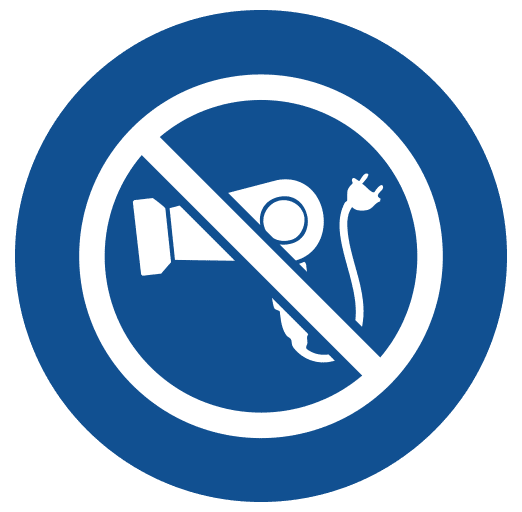

Can I apply heat to shrink sleeves manually (e.g., with a blow dryer)?

Applying heat to shrink sleeves manually is not recommended for professional, uniform results, as it lacks consistent heat. This can lead to bubbling, scorching, incomplete shrinking; dedicated heat tunnels (steam, electric, or radiant) provide far superior consistency and finish quality.

Can barcodes or UPC codes be printed on shrink sleeves?

Yes, barcodes and UPC codes can absolutely be printed on shrink sleeves, but placement, orientation (vertical is best), and avoiding the seam are crucial for scannability, often requiring opaque white backgrounds for clarity and vector graphics for accuracy on curved surfaces.

Do shrink sleeves offer tamper-evident protection?

Yes, shrink sleeves offer excellent tamper-evident protection by creating a secure seal that must be broken to access the product, indicating any interference, and ensuring product integrity, often with convenient perforations for easy consumer opening. They provide a cost-effective, full-coverage solution for many container types, making it clear if a product has been opened before purchase, especially in food, beverage, and pharmaceutical industries.

Conclusion: Choosing the Right Shrink Sleeve Solution with AFM

Shrink sleeve labeling offers unmatched flexibility, shelf impact, and functionality—making it a smart choice for brands looking to stand out while maintaining compliance and performance. From full 360° coverage and compatibility with uniquely shaped containers to tamper-evident protection and barcode-ready designs, shrink sleeves solve many common packaging challenges when implemented correctly. Understanding material options, sizing requirements, application methods, and lead times is key to a successful project.

At AFM, we help simplify the process. Our full line of shrink sleeve applicators and heat tunnels are designed to deliver consistent, high-quality results across a wide range of products and production speeds. Whether you’re launching a new package, upgrading equipment, or scaling production, AFM’s experienced team is here to help you select the right shrink sleeve solution for your goals—today and as your packaging needs evolve.