Shrink Tunnels for Shrink Sleeve Labeling

Reliable Shrink Tunnel Solutions from AFM Sleeves

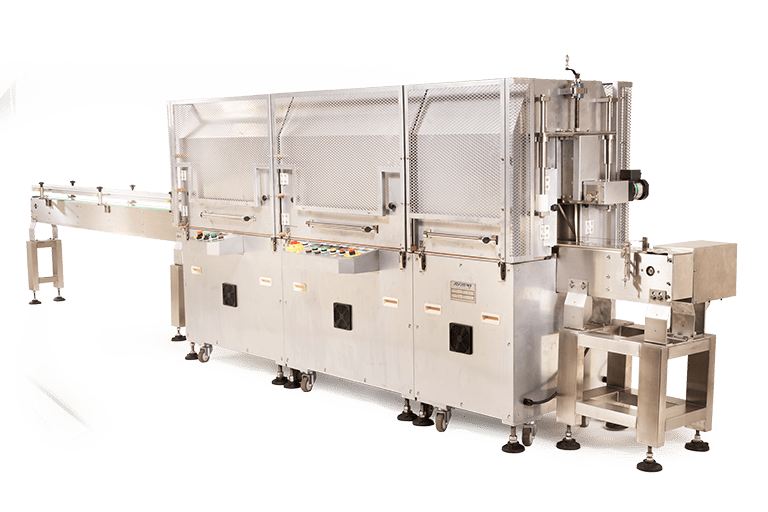

Shrink tunnels are essential packaging systems that apply shrink sleeves with accuracy and consistency, creating a smooth, professional finish on every container. AFM Sleeves is a trusted manufacturer offering a full line of shrink tunnel solutions—steam, electric, and radiant heat—engineered for durability, precision, and energy efficiency. Designed to adapt to a wide range of container shapes and sizes, our shrink tunnels deliver reliable performance for demanding packaging lines in food, beverage, pharmaceutical, and health & beauty industries. With AFM, manufacturers can count on versatile, high-quality equipment that ensures flawless shrink sleeve application and long-term production efficiency.

AFM has the Right Shrink Tunnel You

Choosing the right shrink tunnel is essential for achieving the best results for your shrink sleeve labeling and tamper-evident banding operations. Whether you’re working with food and beverage, pharmaceuticals, or consumer goods, your choice of a steam or non-steam heat tunnel can impact both the quality and efficiency of your production line.

Steam Heat Tunnels: How They Work

Steam heat tunnels use the power of steam to evenly apply heat to shrinkable materials, ensuring a smooth, consistent shrink around containers. Steam heat tunnels are especially effective for handling complex container shapes and various shrink films like PVC, PETG, OPS, and PLA. Our WSN Series Steam Heat Tunnels and WSN-GEN S are examples of highly efficient steam tunnels designed to meet diverse shrink labeling needs.

The WSN Series is equipped with multiple steam zones, allowing for precise heat application, even for full body and cap shrink applications. These tunnels are perfect for industries such as food & beverage, pharmaceuticals, and cosmetics. For situations where in-plant steam is unavailable, the WSN-GEN S includes a built-in steam generator, making it an excellent choice for facilities without existing steam infrastructure.

Non-Steam Heat Tunnels: How They Work

Non-steam heat tunnels, such as the SRT-2500 Electric Heat Tunnel, GS Series Radiant Heat Tunnels, and OAL Classic Radiant Heat Tunnel, use electric and radiant heat to shrink labels. These systems are ideal for applications where steam is either impractical or undesirable. Non-steam heat tunnels are particularly effective for sleeving powdered products, empty containers, or products sensitive to moisture exposure.

The SRT-2500 electric heat tunnel provides uniform shrink results without the need for steam, making it perfect for products where moisture is a concern. The GS Series Radiant Heat Tunnels and OAL Classic utilize high-efficiency blowers and adjustable heater elements to provide precision shrink results, especially in smaller applications or where quick changeovers are required.