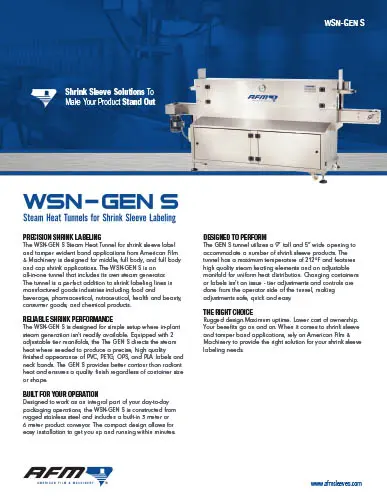

The WSN-GEN S Steam Heat Tunnel For Shrink Sleeve Labeling

+ Middle, full body, and full body and cap shrink applications

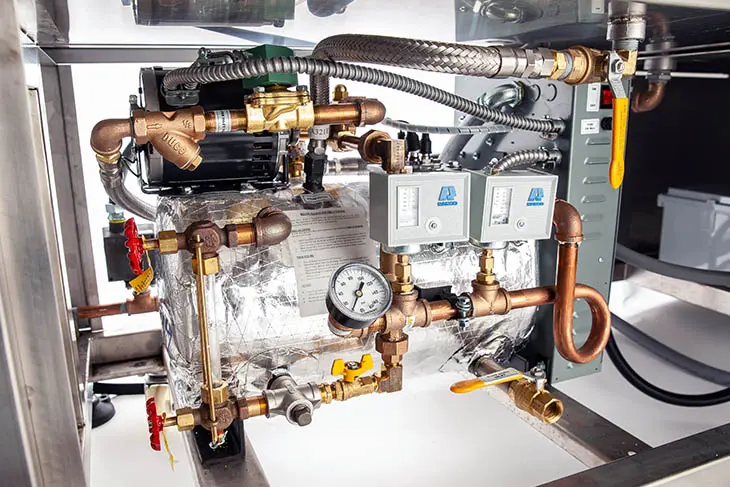

+ Equipped with 4 adjustable tier manifolds

+ Accommodating 9” tall and 5” wide opening

The WSN-GEN S Steam Heat Tunnel for shrink sleeve label and tamper evident band applications from American Film & Machinery is designed for middle, full body, and full body and cap shrink applications. The WSN-GEN S is an all-in-one tunnel that includes its own steam generator. The tunnel is a perfect addition to shrink labeling lines in manufactured goods industries including food and beverage, pharmaceutical, nutraceutical, health and beauty, consumer goods, and chemical products.

Reliable Shrink Performance

The WSN-GEN S is designed for simple setup where in-plant steam generation isn’t readily available. Equipped with 4 adjustable tier manifolds, the The GEN S directs the steam heat where needed to produce a precise, high quality finished appearance of PVC, PETG, OPS, PLA labels and neck bands. The GEN S provides better contour than radiant heat and ensures a quality finish.

Designed to Perform

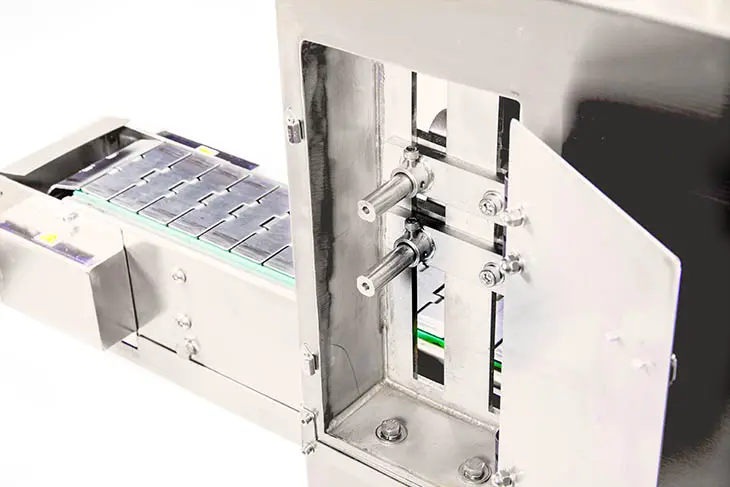

The GEN S tunnel utilizes a 9” tall and 5” wide opening to accommodate a number of shrink sleeve products. The 4 adjustable steam manifolds direct steam horizontally, vertically, or radially to ensure uniform heat distribution. Changing containers or labels isn’t an issue – tier adjustments and controls are done from the operator side of the tunnel, making adjustments safe, quick and easy.